Introduction

As cities grow and industrial activities intensify, managing wastewater effectively is more important than ever. Sewage Treatment Plants (STPs) are critical to ensuring that wastewater is cleaned and returned to the environment safely. However, implementing an STP isn’t as simple as setting up a plant. It involves the collaboration of many industries, with chemical companies playing a vital role in making these systems efficient and sustainable. Companies like Amogh Chemicals are at the forefront of this revolution, providing essential chemicals and innovative technologies that help STPs function smoothly while contributing to a cleaner, greener world.

What is a Sewage Treatment Plant (STP)?

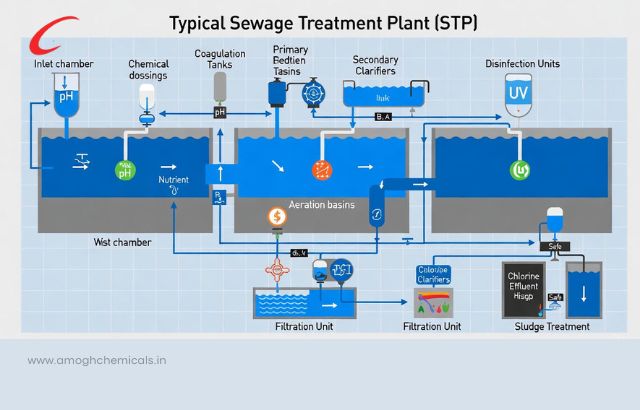

A Sewage Treatment Plant (STP) is a facility designed to treat wastewater before it is released back into the environment or reused. STPs employ a combination of physical, chemical, and biological processes to remove contaminants such as solids, bacteria, and harmful chemicals from sewage water. The end goal is to produce clean water that can be safely discharged into rivers or reused for irrigation, industrial purposes, or even drinking water.

How Chemical Companies Contribute to STP Success

1. Supplying Essential Water Treatment Chemicals

Chemical companies provide the raw materials necessary to optimize various stages of water treatment. These chemicals play a critical role in coagulation, flocculation, disinfection, and pH adjustment.

Examples of Key Chemicals:

- Coagulants & Flocculants: Help remove suspended particles by binding them into larger particles for easier removal.

- Disinfectants (Chlorine, Ozone): Kill harmful pathogens and bacteria to ensure safe water.

- pH Adjusters: Regulate the acidity or alkalinity of the water, optimizing the biological treatment process.

For example, Amogh Chemicals provides high-performance coagulants and flocculants that enhance the primary treatment phase of wastewater treatment. These products improve the removal of suspended solids and make subsequent treatment stages more efficient.

2. Innovation in Water Treatment Technologies

Chemical companies don’t just supply chemicals—they also drive innovation. By developing advanced chemical processes, companies like Amogh Chemicals introduce new ways to optimize the efficiency of STPs. These innovations can reduce operational costs, lower chemical consumption, and improve treatment quality.

For instance, Amogh Chemicals has pioneered new chemical formulations that reduce sludge volume and improve dewatering processes, ensuring better efficiency and lower operational costs for STP operators.

3. Expert Consultation and Design Assistance

Many chemical companies offer consulting services, helping municipalities and industries design and implement STPs. From providing chemical dosing systems to advising on plant optimization, chemical companies ensure that STPs operate effectively and in compliance with environmental regulations.

Responsibilities of Chemical Companies in STP Projects

1. Chemical Supply and Production

Chemical companies are responsible for the manufacture and supply of the chemicals used throughout the sewage treatment process. This includes ensuring that the chemicals are safe, effective, and compliant with local and international environmental standards.

2. Research and Development (R&D)

Chemical companies continually invest in R&D to discover new ways of enhancing water treatment. Their R&D efforts focus on improving the efficiency of treatment chemicals, reducing their environmental impact, and integrating cutting-edge technologies like membrane filtration and advanced oxidation processes.

3. Training and Education

In addition to product development, chemical companies also help train engineers and water treatment professionals. They offer workshops, educational resources, and even collaborate with universities to foster knowledge and innovation in water treatment technologies.

Amogh Chemicals’ 5000 LPD Sewage Treatment Plant: A Step Towards Sustainable Water Management

Project Overview:

In a significant move towards sustainable water management, Amogh Chemicals has successfully commissioned a state-of-the-art Sewage Treatment Plant (STP) with a daily treatment capacity of 5,000 liters. Designed to treat domestic waste, this advanced STP employs the latest treatment processes to ensure that the effluent produced is of the highest quality, meeting or even exceeding local environmental standards. By implementing cutting-edge technology, the plant effectively reduces water pollution, ensuring that treated water can either be safely returned to the environment or reused for various purposes.

This initiative is part of Amogh Chemicals’ ongoing commitment to improving water quality and reducing the environmental impact of wastewater. With water conservation and pollution control becoming increasingly important, the new STP serves as an exemplary model of how technology and innovation can play a vital role in environmental protection.

Sustainability Impact:

The installation of this 5,000 LPD Sewage Treatment Plant goes beyond just treating wastewater; it reflects Amogh Chemicals’ dedication to environmental stewardship. As part of the company’s sustainability agenda, the project contributes to reducing the strain on natural water sources, supports the efficient use of water resources, and helps in maintaining cleaner ecosystems.

By utilizing advanced treatment processes, the plant ensures that harmful pollutants are effectively removed, enabling the treated water to meet strict quality standards. This directly supports Amogh Chemicals’ commitment to responsible water management, promoting sustainable water use in urban areas where wastewater treatment is critical.

With this project, Amogh Chemicals not only tackles water pollution but also helps reduce the carbon footprint associated with conventional wastewater treatment methods, ultimately advancing their broader goals of sustainability and environmental responsibility

FAQs

1. How do chemicals improve sewage treatment?

Chemicals like coagulants help remove suspended solids, disinfectants eliminate harmful pathogens, and pH adjusters optimize the conditions for biological treatment. Together, these chemicals enhance the overall treatment process.

2. Are chemicals in STPs harmful to the environment?

When used responsibly and in correct dosages, treatment chemicals are designed to be safe. However, overuse or improper disposal can lead to environmental damage, which is why strict regulatory standards are followed.

3. How do chemical companies reduce energy consumption in STPs?

By developing more efficient chemical treatments and processes, chemical companies help optimize the energy usage in STPs. For example, new flocculants can reduce the amount of sludge, cutting down on energy-intensive sludge handling.

For Chemical Engineering Students: A Guide to Water Treatment Careers

Students pursuing chemical engineering or chemical technology can gain significant hands-on experience in the water treatment sector by working on projects that directly address real-world challenges. Engaging with chemical companies, like Amogh Chemicals, will provide valuable insights into the latest treatment technologies and innovations. By gaining practical knowledge in water chemistry, process optimization, and sustainability, students can contribute to developing cleaner, more sustainable water treatment solutions.

Conclusion

The role of chemical companies in STP implementation is indispensable. From providing essential chemicals to driving technological innovation, these companies ensure that sewage treatment plants operate efficiently, sustainably, and in compliance with regulatory standards. As the world continues to focus on sustainability and resource conservation, the contributions of chemical companies like Amogh Chemicals will be crucial in shaping the future of water treatment.